Inventory Management Database

I created a database for inventory and warehouse management for a company that manufactures semi-custom accessories for kitchen appliances. They produced about 350 unique designs that were compatible with a variety of different stove range and cooktop model numbers. Each design was available in either Lite or Premium material, and Black or Silver color. All four of these variations (Lite Black, Lite Silver, Premium Black and Premium Silver) needed to be kept in stock. A few designs were also offered in Copper Lite and Gold Lite, but since they were less popular, those variations were made to order. There were two main ways the products were manufactured, either one at a time on a Zund (CNC) machine, or several at a time with a die board using a clicker press.

We were having trouble finding a software that would work for us out of the box, primarily because our SKU to product ratio was not one-to-one. For example, let's say product number 100 was compatible with four different stove models: AAA, BBB, CCC and DDD. In our Shopify store we could list a SKU for a 1-pack and 3-pack of each material and color for product 100. But on Amazon we would need to include the model number within the SKU becuase of the constraints of their system. So the 100 Lite Black product alone would have the following SKUs coming from that one stock level (these are not the actual SKUs but simplified for demonstration purposes):

- 100-LT-BLK (Shopify 1-pack)

- 100-LT-BLK-3X (Shopify 3-pack)

- 100-LT-BLK-AAA (Amazon 1-pack for model AAA)

- 100-LT-BLK-BBB (Amazon 1-pack for model BBB)

- 100-LT-BLK-CCC (Amazon 1-pack for model CCC)

- 100-LT-BLK-DDD (Amazon 1-pack for model DDD)

Most of the warehouse management softwares I looked into were set up to simply keep track of a SKU coming from a specific location in the warehouse in a one-to-one ratio. We needed a database that would be able to group together all the SKUs that were coming from the same stock shelf.

The database would need to be able to keep track of current stock levels of both raw/uncut materials, plus the finished/cut products that were on the shelves. Each finished product would need minimum stock and restock numbers so that workers would know when the product stock needed replenished, and how much to cut of each one. The database should include bin locations for each product both for the purpose of restocking the shelves and for picking current orders. Additionally we should be able to keep track of waste in the production process, as well as what packaging was used to keep track of our box stock levels.

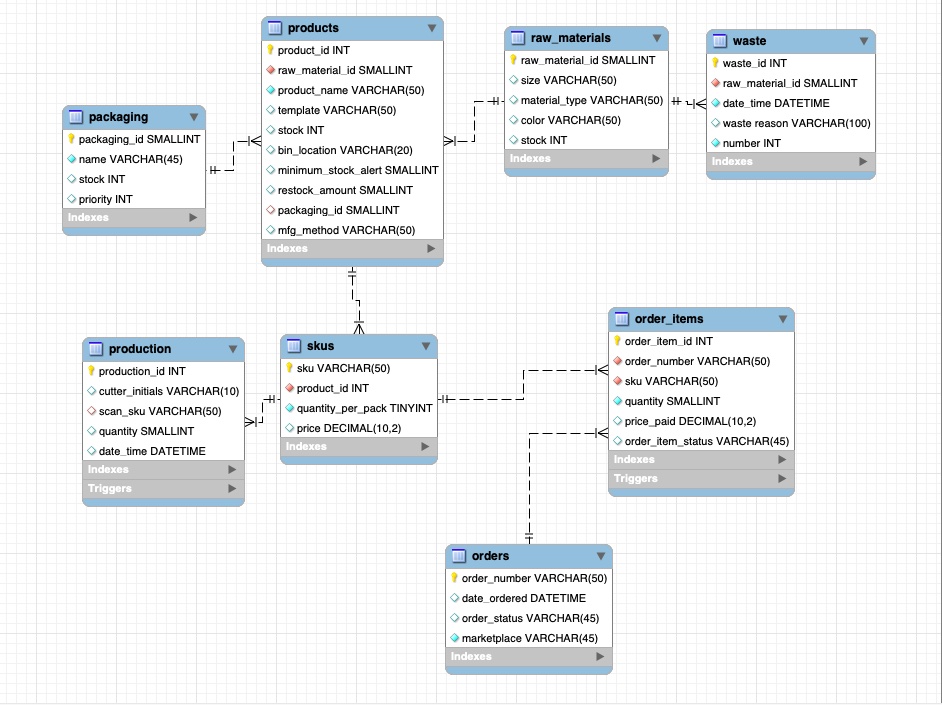

MySQL Database Schema

Workflow

An order comes in through one of the online stores and updates the orders and order_items tables. The current stock levels in the products table are diminished by the correct amount based on the SKUs in order_items. A pick_list view is generated for unfulfilled orders, and warehouse workers use that list to pick and pack. In the meantime, as product stock levels decrease below their minimum_stock_alert number, they are included in a cut_list view for the members of the production team. They cut the amount stated and update the production table with the appropriate information. The scan_sku for each product is the basic Shopify 1-pack SKU, which needs mapped onto the correct product and added to its stock levels. At the same time the raw_materials table needs the stock diminished for the raw materials used in production.

Triggers

Diminishing Product Stock Based On Order Items

DROP TRIGGER IF EXISTS update_product_stock_order_items;

DELIMITER $$

CREATE TRIGGER update_product_stock_order_items

AFTER INSERT ON order_items

FOR EACH ROW

BEGIN

UPDATE products

SET stock = stock - (NEW.quantity *

(SELECT quantity_per_pack

FROM skus

WHERE sku = NEW.sku))

WHERE product_id =

(SELECT product_id

FROM skus

WHERE sku = NEW.sku);

END $$

DELIMITER ;

Diminishing Raw Material Stock Based On Production

DROP TRIGGER IF EXISTS update_raw_material_stock_production;

DELIMITER $$

CREATE TRIGGER update_raw_material_stock_production

AFTER INSERT ON production

FOR EACH ROW

BEGIN

UPDATE raw_materials

SET stock = stock - NEW.quantity

WHERE raw_material_id =

(SELECT raw_material_id

FROM products

WHERE product_id =

(SELECT product_id

FROM skus

WHERE sku = NEW.scan_sku));

END $$

DELIMITER ;

Increasing Product Stock Based On Production

DROP TRIGGER IF EXISTS update_product_stock_production;

DELIMITER $$

CREATE TRIGGER update_product_stock_production

AFTER INSERT ON production

FOR EACH ROW

BEGIN

UPDATE products

SET stock = stock + NEW.quantity

WHERE product_id =

(SELECT product_id

FROM skus

WHERE sku = NEW.scan_sku);

END $$

DELIMITER ;

Views

Pick List View

This is the pick list for the entire list of unfulfilled order items, excluding warranties and other intangible products, and sorted by bin location to ensure efficient picking.

CREATE OR REPLACE VIEW pick_list AS

SELECT

p.product_name,

(SELECT bin_location FROM products WHERE p.product_name = product_name) AS bin_location,

SUM(oi.quantity * s.quantity_per_pack) AS quantity_to_pick

FROM order_items oi

JOIN skus s USING (sku)

JOIN products p USING (product_id)

WHERE order_item_status = 'pending' AND sku NOT LIKE '%warranty' AND sku NOT LIKE 'SS%'

GROUP BY p.product_name

ORDER BY bin_location

Cut List View

The cut list is sorted both by what machine is used in production and what type and color of raw material is needed. If a stock level dips below zero, the cut amount should include the standard restock level for that product, plus however much it has gone below zero. This ensures that the cut_now amount will cover all current orders plus the standard stock level.

CREATE OR REPLACE VIEW cut_list AS

SELECT

p.product_name,

p.bin_location,

(CASE

WHEN (p.stock < 0) THEN (p.restock_amount - p.stock)

ELSE p.restock_amount

END) AS cut_now,

p.mfg_method,

rm.size,

rm.material_type,

rm.color,

p.stock

FROM products p

JOIN raw_materials rm

USING (raw_material_id)

WHERE

p.stock <= p.minimum_stock_alert

AND p.mfg_method IS NOT NULL

ORDER BY p.mfg_method , rm.material_type , rm.color;

Box Report

Packaging has been given a priority number based on how large it is. The largest box is Priority 1, the next largest Priority 2 and so on. When multiple items are ordered, the packaging chosen must accommodate the largest item in the order. The box report has been designed to concatenate all order items and boxes needed for an order, and list the highest priority box first.

CREATE OR REPLACE VIEW box_report AS

SELECT

oi.order_number,

group_concat(p.product_name ORDER BY p.product_name) AS items,

group_concat((SELECT name FROM packaging WHERE packaging_id =p.packaging_id)

ORDER BY (SELECT priority FROM packaging WHERE packaging_id = p.packaging_id)) AS boxes

FROM order_items oi

JOIN skus s USING (sku)

JOIN products p USING (product_id)

WHERE p.packaging_id != 7

GROUP BY order_number

ORDER BY boxes

Refining the Pick List Process

The picking/packing team don't normally pick the entire list of unfulfilled orders all in one go. They'll split the list up into groups of about 30 orders each based on common items, then print out the shipping labels associated with the orders just picked. The process is a bit slow and tedious, so I wanted to find a way to streamline it and let the database handle grouping together similar order items and creating subsets of the entire pick list accordingly.

Concatenated Pick List

The concatenated pick list is designed to sort pending orders based on included items and then limit it to the first 30 orders.

CREATE OR REPLACE VIEW concat_pick_list AS

SELECT

o.date_ordered,

oi.order_number,

group_concat(p.product_name ORDER BY p.product_name) AS items,

group_concat(p.bin_location ORDER BY p.bin_location) AS bins

FROM order_items oi

JOIN skus s USING (sku)

JOIN products p USING (product_id)

JOIN orders o USING (order_number)

WHERE order_item_status = 'pending' AND sku NOT LIKE '%warranty' AND sku NOT LIKE 'SS%'

GROUP BY order_number

ORDER BY bins

LIMIT 0,30

Subset Pick List

The subset pick list is exactly the same as the original pick list for all unfulfilled orders, but now includes the exact 30 orders listed in the concatenated pick list.

CREATE OR REPLACE VIEW subset_pick_list AS

SELECT p.product_name,

(SELECT bin_location FROM products WHERE p.product_name = product_name) AS bin_location,

SUM(oi.quantity * s.quantity_per_pack) AS quantity_to_pick

FROM order_items oi

JOIN skus s USING (sku)

JOIN products p USING (product_id)

WHERE order_number IN (SELECT order_number FROM concat_pick_list)

GROUP BY p.product_name

ORDER BY bin_location

Next Steps

Now that the database is working smoothly within MySQL, our next steps would be to set up an API connection to the marketplaces and our shipping software so that the orders and order_items tables get live updates. Additionally, it would be beneficial to set up a simple user interface for the workers in the warehouse to be able to access the views and update the production table.